best-in-class

regenerable ion exchange systems

For Industrial Wastewater Recycling, Deionization & Metal Scavenging employing cutting-edge technologies, innovative engineering and high-quality components. Building our best system ever - every time for 20 years.

Building our best system ever - every time is more than just a slogan or line on our logo. It’s who we are and what we do, which has made us one of the most highly-regarded industrial wastewater treatment equipment manufacturers.

With 20 years of experience & expertise in metal-bearing waste treatment, we specialize in regenerable ion exchange systems for rinsewater recycling & deionization and wastewater metal scavenging for printed circuit board manufacturing, metal finishing & anodizing, and plating on plastics (POP).

OUR MIssion

Since our inception in 2005 as an OEM for Kinetico Engineered Systems whose innovative regenerable ion exchange engineering we licensed in 2007, we’ve strived every day to make our Best-in-Class systems even better.

We began with superior engineering like counter-current regeneration of packed deionization resin beds, requiring 50% less acid and 60% less caustic, therefore 50-60% less rinsing, twice as efficient as co-current systems. And Kinetico’s unique “feed-forward” regeneration that ensures consistent deionized water quality by triggering independent cation & anion resin regenerations BEFORE exhausted by measuring feedwater conductivity and totalizing flow to calculate independent resin loading.

Based on our experience, we’ve optimized our systems in unique ways, including for example by measuring product water pH as an indication of whether the cation or anion resin is exhausted and triggering regeneration of only one or the other, further increasing operating efficiency compared to simultaneously regenerating both resins as is typically done.

Continually improving systems operation, we routinely update installed systems human machine interface through remote access to the PAC & HMI by a managed switch which also enables us to provide ongoing technical support and most recently cloud data-logging for system optimization.

At the same time we’ve increasingly standardized our systems, lowering our costs for engineering & manufacturing and by extension selling price, even while performance was improved with higher reliability, simplified operation & maintenance, reduced operating cost and most importantly consistent product water quality.

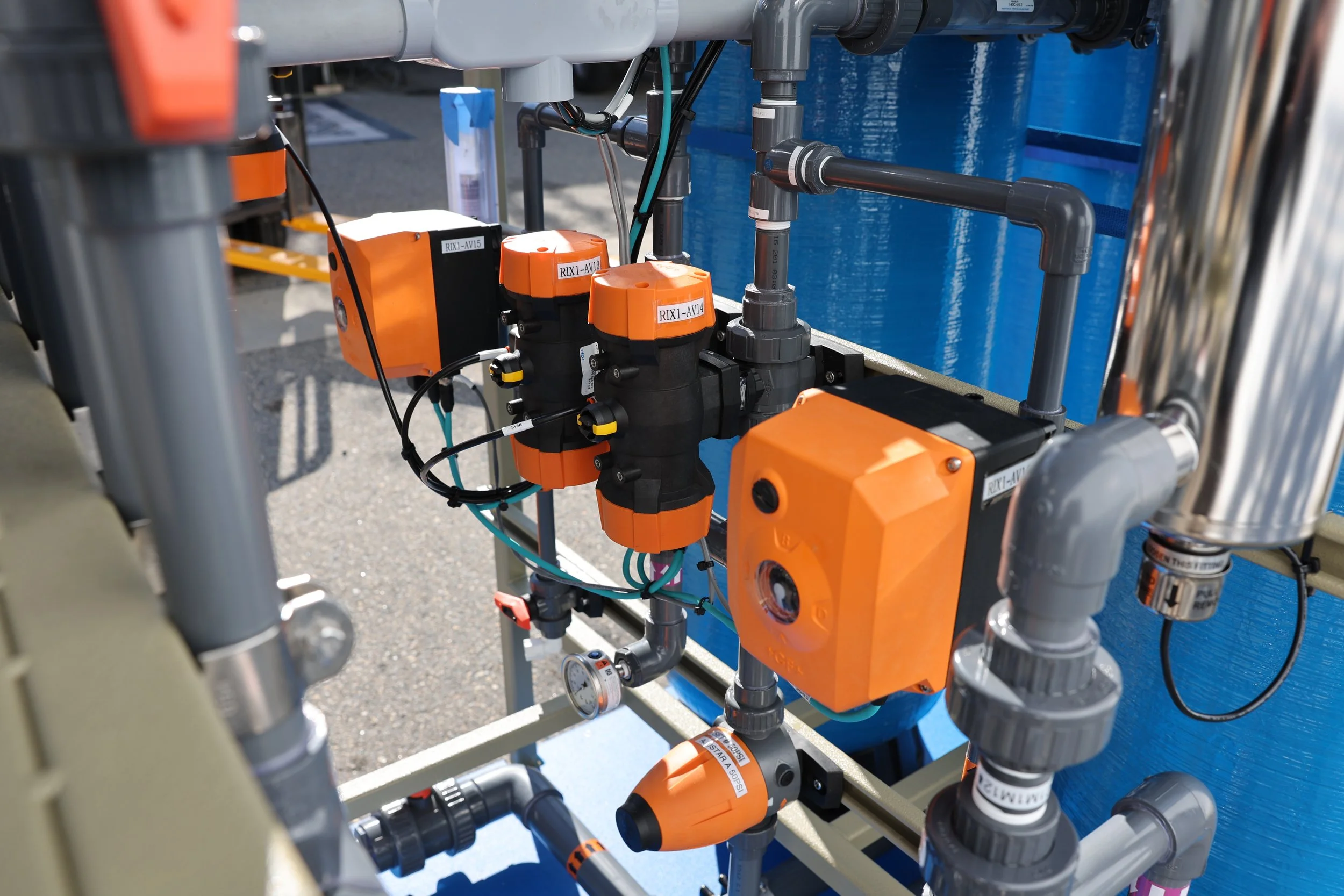

Key to our success has been long-term relationships with best-in-class component suppliers, especially +GF+ whose Piping & Signet measurement and control systems have been integral to every system we’ve built for 20 years. And Rockwell Automation, which we’re a Silver OEM Partner and whose Allen Bradley CompactLogix and PanelView control our systems with seamless software integration and unparalleled performance & reliability.

FEATURED

OUr Systems

We engineer, manufacture, install & provide support for systems including:

Water Innovations Regenerable Ion Exchange (WI-RIX) our newest system for recycling industrial rinsewater with TDS <500-ppm, pH 3 to 10 and TSS <25-ppm to produce deionized water with <5% waste.

High-Flow Ion Exchange (HFX) Manufactured by WI for 17-years, it’s standardized to deionize industrial rinses at 35, 55, 75, 115 or 135 GPM, employing a multi-skid design varying only by the size of its pumps, media & resin vessels, and interconnect piping.

Metal Scavenging WI-RIX-MS & HFX to selectively-remove metals to meet discharge limits or precious metals for their electrolytic recovery, based on standard designs but requiring customization based not only on flow rate but also metal concentration and other service factors.

Proprietary Media Filtration to remove suspended solids, O&G, organics or oxidizers by proprietary GAC-coated ceramics as pre-treatment to protect the following ion exchange from being damaged.

Waste Treatment including continuous (WI-CT) and Batch (WI-BT) pH adjust & metal precipitation systems for non-recyclable rinses and concentrated wastes to meet regulatory discharge limits, routinely required in combination with our regenerable ion exchange systems.

Our Customers

While we remain focused on recycling metal-bearing industrial rinsewater, our customer base has expanded & evolved as manufacturing in the US has diminished over the past 20 years.

We began in 2005 with printed circuit board (PCB) manufacturers because 65% of their wastewater is compatible with recycling by regenerable ion exchange and they require a significant volume of 1 to 15 uS water which regenerable ion exchange easily produces.

Coming out of the “great recession” in 2010 as PCB manufacturing was decreasing in the US by off shoring, we turned to general metal finishers which, while more complicated with various metals plating and requiring less DI water, were also potential candidates for rinsewater recycling.

We quickly discovered and were discovered by aerospace anodizers, as a more suitable candidate for rinsewater recycling owing primarily to their need for high volumes of DI water to meet their customer’s product quality requirements, which have remained a primary focus for us.

We also found need for our systems by plating on plastics (POP) facilities primarily for automotive parts considering their utilization of multiple cleaning and metal plating steps requiring high volumes of DI water to ensure product quality.

As we established ourselves as a best-in-class manufacturer of regenerable ion exchange systems, we have been sought out by many other customers with metal-finishing related applications suitable for our systems.

Bottom-line, we’re able to support any facility looking to closed-loop recycle industrial rinses into DI water or needing to remove regulated metals to meet discharge limits, are potential customers for our systems we’d be glad to connect with.

Standardized Skid-mounted Systems

WI-RIX SERIES

REGENERABLE ION EXCHANGE

Our newest standardized system, the single skid WI-RIX is customized for wastewater recycling, deionization or metal scavenging up to 25-gpm continuous service with redundant duplex media & bag filters and alternating duplex resin vessels

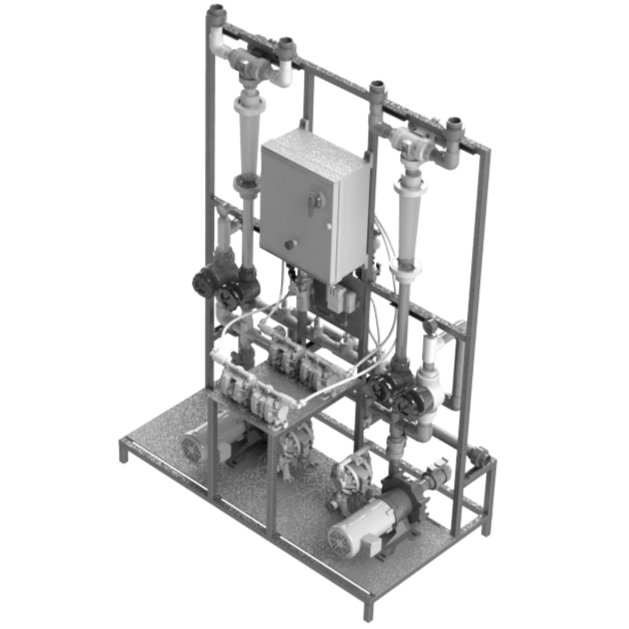

HFX SERIES

HIGH FLOW ION EXCHANGE

Inherited from Kinetico Engineered Systems and incorporating all of the features of the WI-RIX, the multi-skid HFX is available from 35 to 135-gpm of continuous service, based on columns size and tanks volumes, with redundant alternating duplex feed & DI water pumps providing 24/7 operation

Batch & CONTINUOUS

WASTEWATER TREATMENT

Generally combined and integrated with WI-RIX and HFX systems, Water Innovations Batch Treatment (WI-BT) and Continuous Treatment (WI-CT) are built upon our 20 years of experience with wastewater treatment and knowledge of proprietary metal precipitants & coagulants

Ready to Rethink Water in Your Process?

Contact Water Innovations today to discuss a tailored solution for you.

Beyond Equipment

We don’t just deliver systems; we build long-term partnerships. Our comprehensive services include:

Engineering & Process Analysis

On-Site Installation & Startup

Operator Training & Documentation

Remote Monitoring & Technical Support

Maintenance & System Upgrades

With our in-house fabrication, testing, and service team, we ensure every solution performs to spec — on day one and for years to come.