Industrial Wastewater Treatment

WI-BT SERIES

BATCH TREATMENT

The WI-BT system is designed for Precipitation, Oxidation-Reduction, and Neutralization of wastewater in batches up to 2000 Gallons.

DOWNLOADS

UP TO 2000 GALLONS

WI-CT SERIES

CONTINUOUS TREATMENT

The WI-CT system is designed for Precipitation, Oxidation-Reduction, and Neutralization of wastewater continuously up to 50 GPM.

DOWNLOADS

UP TO 50 GPM

WI-BT SERIES

Batch-Treatment Simplified

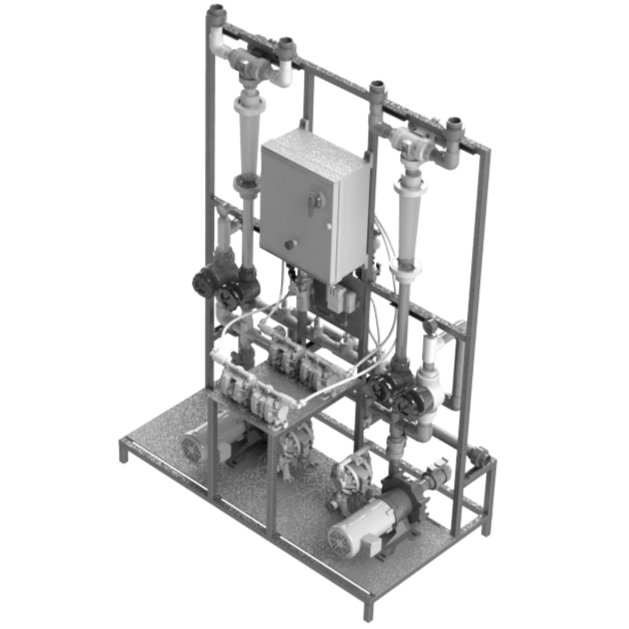

The Water Innovations Batch-Treatment (WI-BT) System offers an innovative, skid-mounted solution for comprehensive wastewater management, specializing in Precipitation, Oxidation-Reduction, and Neutralization. Designed to streamline your process, the WI-BT system utilizes a single pump for incoming waste transfer, in-tank mixing, filter press feed, and treated water discharge to the POTW (Publicly Owned Treatment Works).

Core Capabilities and Process

This robust system is built for effective treatment, including acid/caustic pH adjustment, metals precipitation, and chrome reduction, and supports the addition of flocculent. Optional bleach can be added for Cyanide (CN) oxidation. The system is designed to handle a maximum metals concentration of 1,000 mg/L.

Key components include:

Treatment Tank: Features a cone-bottom design and uses four (4) floats to control incoming waste, process activation, discharge, and sludge transfer. Internal mixing is provided by in-tank eductors. Discharge is routed through a clear pipe with an integrated sample tap. The typical Batch Treatment Cycle takes just 3 to 5 Hours.

Chemical Dosing: Chemicals are added into the recirculating water using Double-Acting Air Diaphragm Pumps (AODD) and efficiently mixed by the in-tank ejectors. Chemical feed control is precise, utilizing pH and ORP sensors. The system operates within a pH Range of 2-12 SU.

Waste Tanks: Standard configurations include one (1) Acid and one (1) Alkaline waste tank, each equipped with a pressure sensor to monitor tank levels (0-100%) and regulate automatic waste transfer to the treatment tank.

Standard Sizes and Specifications

The WI-BT system is available in two standard sizes to fit your operational needs:

WI-BT-1000 (Small)

Treatment Tank Capacity: < 1,000 Gal

System Pump: 1” AOD Pump

Fill/Empty Maximum Flow: 53-gpm

Sludge Tank Capacity: 300 Gal

Maximum Filter Press Feed: 5-ft³

WI-BT-2500 (Large)

Treatment Tank Capacity: < 2,500 Gal

System Pump: Treatment Tank Capacity: 1.5” AOD Pump

Fill/Empty Maximum Flow: 123-gpm

Sludge Tank Capacity: 1,000 Gal

Maximum Filter Press Feed: 10-ft³

The physical skid size is compact at 48" L x 24" W with a shipping weight of 1,200-lbs. The frame construction uses 304SS (Stainless Steel) with a polyurethane protective coating, and interconnect piping is schedule 80 PVC.

Advanced Automation and Control

Our Human Machine Interface (HMI) features intuitive, operator-friendly controls that distinguish our system, offering advanced automation without the substantial cost of competing systems.

Controller: Utilizes an AB CompactLogix Automation Controller and an AB PanelView 7 Plus 7" Touchscreen.

Monitoring: The HMI provides system monitoring, displaying pH, ORP, and tank levels, along with the operating status of the system pumps.

Security & Access: Access Control is managed through multi-level passwords, and the system supports Ethernet-based remote access.

Filter Press Control (Optional): We offer an optional Auto Pump Controller (APC) which intelligently increases the feed pump air supply in direct response to increasing filter press back-pressure.

Installation and Utilities

Installation is straightforward: customers with basic plumbing and electrical skills can readily install the system, requiring single points of connection for utilities.

Electrical: 120vac-1Ø power (Full Load Amps: 15).

Compressed Air: 50-scfm of air.

Water Innovations can provide turn-key installation and start-up services, or we can oversee customer-led installation. We also offer Tank Kits, including required schedule 80 PVC adaptors, isolation & check valves, and level sensors for customers who provide their own tanks.

WI-CT SERIES

Effective Continuous Treatment

The Water Innovations Continuous Treatment (WI-CT) System is a culmination of nearly 20 years of experience, designed to be an efficient, integrated, or stand-alone skid engineered to handle various processes, including pH adjustment, metals precipitation, Cr6+ reduction, and CN oxidation, often utilizing one or two treatment tanks.

System Design and Configurations

The WI-CT system can be configured as a Simplex or Duplex setup. Simplex systems are typically sufficient for Cr6+ reduction or pH-adjust of neutral wastewater. Duplex systems are generally required for more complex tasks such as CN oxidation, pH-adjustment of concentrated waste, or precipitation involving coagulants for solid-liquid separation.

Key features of the design include:

Integrated or Stand-Alone: Systems are available as integrated units, including treatment tanks with necessary components and pre-installed fittings, or as stand-alone skids, with optional Tank Kits for integration with customer-provided tanks.

System Pump: A single pump manages a majority of the fluid movement: it pressurizes incoming waste, recirculates the solution for mixing and chemical dosing, and discharges the treated water. A mag-drive pump is used for pH-adjust systems, while an AODD pump is employed for applications involving suspended solids, such as metal precipitation, Cr6+ reduction, and CN treatment.

Flow Control: Management is achieved using actuated 3-way valves on the pump inlet and outlet. This mechanism splits the flow between the source and receiving tank during normal operation. If the solution is found to be out of specifications, the system recirculates it back to the source tank. In dual tank configurations, the tanks operate in sync to maintain balanced levels.

Waste Handling: Concentrated acid and alkaline wastes can be accumulated in separate holding tanks and slow-fed to the system for self-neutralization, offering an alternative to batch treatment or off-site disposal.

Process Automation and Control

The WI-CT system is distinguished by its intuitive and operator-friendly controls and treatment process automation.

Treatment Tanks: Tanks, whether customer-provided or supplied by WI (flat-bottom dome-top HDLPE), utilize a level sensor to regulate incoming and outgoing flows and pump operation. Mixing is facilitated by eductors pressurized by the recirculating solution.

Chemical Dosing: Chemicals are dosed by AODD or metering pumps (depending on size and application) as the solution recirculates for mixing. Crucially, chemical control is managed by in-line pH and ORP sensors, which simplifies both installation and operation.

Chemical Feed Logic: To ensure precise control and prevent chemical overdosing, chemical feed is increased (greater ON time versus OFF time) as the solution pH moves further away from the mid-point of the operating range, recognizing the logarithmic nature of pH.

Human Machine Interface (HMI): The Overview Screen provides continuous system monitoring, displaying pH, ORP, tank levels, and the operating status of the system pump, flow-control valve, and chemical feed valves. The Settings Screen enables the operator to change pH and ORP setpoints, reaction timers for optimization, and alarm set points. The Trend Screen provides real-time display and historical data-logging of operating pH and ORP, which can be stored on the HMI’s SD card for regulatory submittal.

Control Options: All system components, including mixing/transfer and chemical feed pumps, are automatically controlled during normal operation, but can also be manually activated using virtual Hand-Off-Auto (HOA) switches through the HMI for optimal process control if additional chemical feed is needed.

Specifications and System Models

The system design and method of operation and control remain consistent regardless of size, though the size of the system pump and the number of in-tank mixing eductors increase with the tank size (available for up to 2,500-gallon tanks).

Alternative WI-CT models are identified by specific model IDs, where the last number indicates the system’s peak flow rate:

WI-CT-1 or -2: Indicates single or dual treatment tanks.

WI-CT-1 or 2-C: Includes metered concentrated waste feed.

WI-CT-1 or 2-CN: Designed specifically for cyanide oxidation.

For example, a WI-CT-2-C-CN-30 signifies a system with 2-stages, concentrated waste feed, CN oxidation capability, and a rating for 30-gpm.

Water Innovations can provide an integrated piping and instrument diagram (P&ID) specific to system size (small, medium, or large), which, when combined with optional tank kits, helps achieve a cost-effective, professional system installation.