Water Recycling & Deionization Systems

WI-RIX

Developed to replace the single-skid CIX we licensed from Kinetico and manufactured for 15-years, to recycle or deionize 12- or 25-GPM of rinsewater, it employs all the same components as the HFX except alternating duplex pumps

HFX

A multi-skid system for rinsewater recycling & deionization we’ve manufactured since 2007 with for 35- 55- 75- 115- or 135-GPM service flow with optional duplex pumps, extra pre-treatment & 2nd cation vessels for 5 Megohm

General Specifications and Construction

Configuration: Redundant duplex pre-treatment media vessels and bag filters and alternating duplex cation & anion exchange resin vessels

Product Water: Typically 1 uS/cm (1-MegΩ) with pH ranging from 8.5 to 6.2 as the anion resin exhausts

Required Feed Water: TDS <500 mg/L, TSS <25 mg/L, chlorine <2 mg/L, temperature 55°F – 105°F, pH 3 – 10, and Oil & Grease: Non-detect

Piping: All major piping is constructed of Schedule 80 PVC.

Skid Mounted: Piping and components are integrated on 304SS skids coated with polyurethane to prevent corrosion, with single points of utilities connection.

Feedwater Tank, Pump and Pre-Treatment

Feedwater Tank: Flat-bottom dome-top HDLP with submersible psi sensor to monitor water level to control system operation

Feed Pump(s): Multi-stage constructed of 316SS controlled by Variable Frequency Drive (VFD) for regulated flow and pressure.

Media Filters: Redundant duplex vessels containing Cerapure™ for removal of TSS, organics & oxidizers with automatic backwashing

Bag Filters: Redundant duplex filter housings containing replaceable 5µ bag filter to prevent fugitive media fines from fouling resin

Separate Cation and Anion Exchange

Configuration: Duplex cation and anion exchangers alternating between service, regeneration, and stand-by

Vessel: PE Lined Fiberglass

Resin: Macroporous Strong Acid Cation with 20,000 grains/ft3 and Type II Strong Base Anion with 18,000-grains/ft3 capacity

Packed Bed: With polypropylene inert on top of resin to prevent resin movement during regeneration

Regeneration Chemicals: Counter-current with 4-lbs acid/ft3 cation resin and 6-lbs of caustic/ft3 of anion resin

Regeneration Control: Automatic regulated by measurement of inlet uS, totalized system flow, and outlet uS & pH

Feed-Forward: Based feedwater uS converted to grains/gallon x totalized flow in gallons/min to determine resin loading in grains/min

Feed-Back: Based on outlet pH once outlet conductivity exceeds 15-uS, triggering regeneration of the cation if pH >9 and anion if pH >9

Chemical Supply: 32% HCl or 25-50% H2SO4 for cation and 25-50% NaOH for anion drawn by customer

Controls and Automation

Controller: Allen Bradley CompactLogix programmable automation controller

Human Machine Interface: Allen Bradley 10.4” PanelView Plus touch screen

Instrumentation: +GF+ Signet sensors for inlet & outlet conductivity, system flow & outlet pH

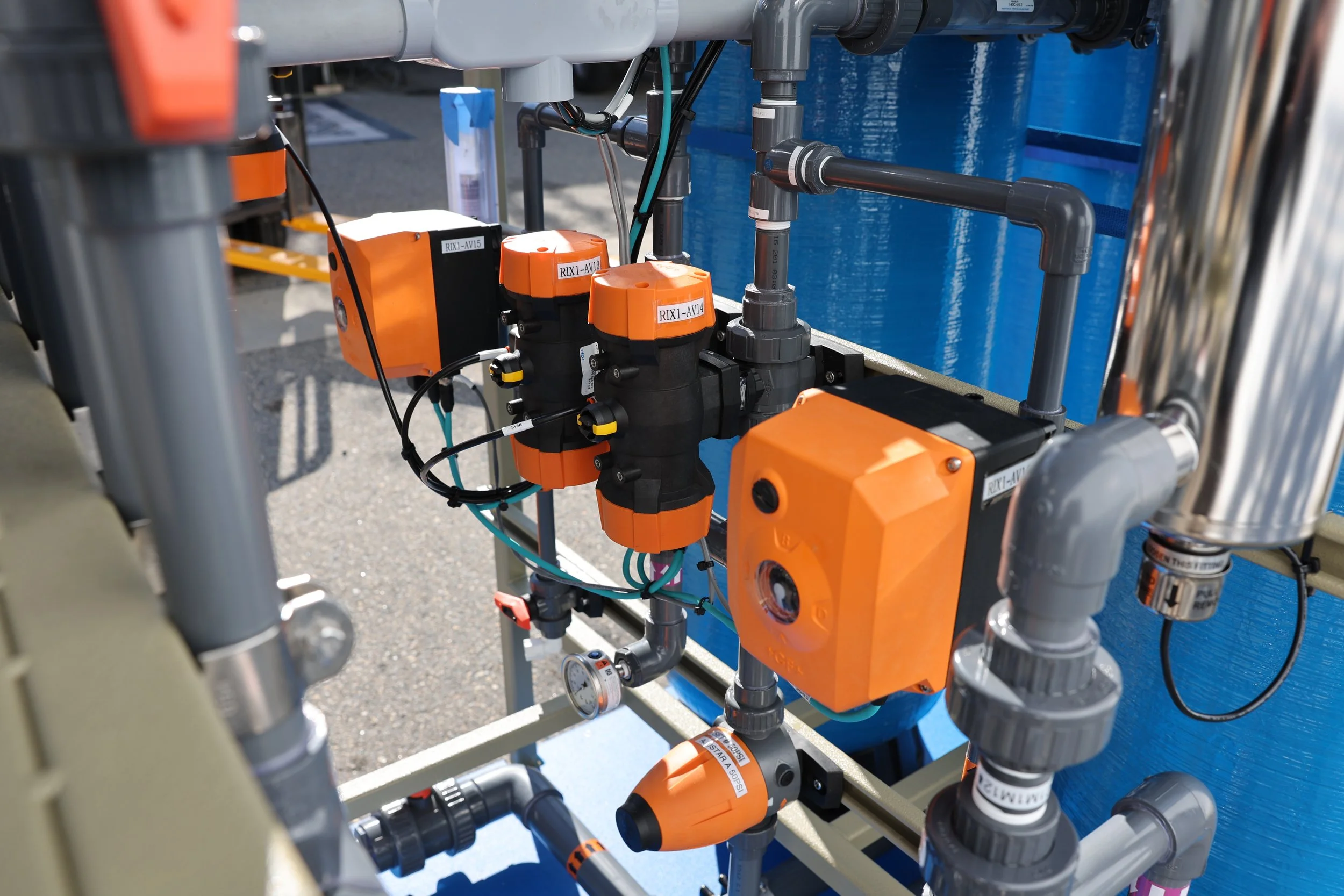

Actuated Valves: +GF+ Piping Systems PPA-actuated Type 543 3-way and 546 2-way ball valves

Chemical Monitoring: Low-level sensors for chemicals to inhibit regeneration and trigger alarm

WI-RIX Single-Skid Systems

Water Innovations Regenerable Ion Exchange or WI-RIX was named to distinguish it from Kinetico’s single-skid CIX we licensed in 2007 and manufactured until they discontinued its key proprietary regeneration valve in 2021, While unexpected & initially disruptive it’s turned out well as the WI-RIX with +GF+ PPA-actuated valves utilized on the HFX for two decades, is more reliable to operate & maintain while preserving the CIX’s other best-in-class features. While the CIX was limited to 12-gpm, the WI-RIX is available as a 25-gpm system (as the WI-RIX-25-WR shown below) for rinsewater recycling & potable water deionization.

Also engineered for metal scavenging on a single skid for ease of installation and space savings, the WI-RIX incorporates all the same components as the multi-skid HFX except duplex feed & DI water pumps. But like the HFX, it includes alternating or redundant duplex pre-treatment backwashable media & replaceable bag filters and cation and anion exchange resin vessels, with both systems now able to utilize the same programmable automation control and human machine interface further standardizing our products.

WI-RIX SYSTEMS

-

Nominal Flow Rate: 12-gpm

System Footprint: 15’ x 15’

Tanks: Minimum 1,000-gallons

Utilities: 15A@480VAC & 5-gpm@60-psi

Pumps: 1.5 HP - 5 Stage

Ion Exchange Vessels: 13” x 54" containing 3-ft³

Cation Exchange Capacity: 60,000 grains

Anion Exchange Capacity: 54,000 grains

Regeneration Consumption and Waste:

Cation Regenerant: 4-gallons 32% HCl & 100-gallons DI water

Anion Regenerant: 2-gallons 50% NaOH & 125-gallons DI water

-

Nominal Flow Rate: 25-gpm

System Footprint: 20’ x 15’

Tanks: Minimum 2,000-gallons

Utilities: 25A@480VAC & 10-gpm@60-psi

Pumps: 2 HP - 7 Stage

Ion Exchange Vessels: 18” x 65" containing 7-ft³

Cation Exchange Capacity: 140,000 grains

Anion Exchange Capacity: 126,000 grains

Regeneration Consumption and Waste:

Cation Regenerant: 9-gallons 32% HCl & 250-gallons DI water

Anion Regenerant: 4.5-gallons 50% NaOH & 295-gallons DI water

WI-RIX DOWNLOADS

HFX Multi-Skid High FLow Ion Exchange

The HFX multi-skid system for wastewater recycling and water deionization was originally designed by Kinetico Engineered Systems that we licensed in 2007 and have been manufacturing for 18 years. Available for service flow rates of 35-, 55-, 75-, 115- and 135-GPM, the system design is the same regardless of flow rate except for the size of its tanks, pumps, filter media and resin vessels and interconnect piping, with redundant duplex media vessels & bag filters and alternating duplex cation and anion resin vessels, with optional alternating duplex or simplex system feed and DI water pumps to guarantee a continuous supply of deionized water.

HFX SYSTEMS

-

System Flow Rate: 35 gpm

Approximate Footprint: 10’ x 16’ x 10’ H (Duplex Series)

Tanks:

Minimum Feed Rinsewater Tank Volume: 1,500 gallons

Minimum DI Water Holding Tank Volume: 2,500 gallons

Pumps & Utilities:

Feed Pump Horsepower: Two (2) 5 HP.

DI Water Pump Horsepower: Two (2) 5 HP.

Electrical Utility: Full Load Amps (FLA) 80/40 (208-230/460V).

Make-up Water Requirement: 10 gpm.

Ion Exchange Details:

Resin Volume per Vessel: 14 ft³.

Total Cation Grains Capacity: 280,000 grains.

Total Anion Grains Capacity: 252,000 grains.

Regeneration Consumption/Waste:

32% HCl per Cycle: 18 gallons.

50% NaOH per Cycle: 10 gallons.

Cation Waste per Cycle: 543 gallons.

Anion Waste per Cycle: 690 gallons.

-

System Flow Rate: 55 gpm

Approximate Footprint: 10’ x 16’ x 10’ H (Duplex Series)

Tanks:

Minimum Feed Rinsewater Tank Volume: 2,000 gallons

Minimum DI Water Holding Tank Volume: 3,000 gallons

Pumps & Utilities:

Feed Pump Horsepower: Two (2) 7.5 HP.

DI Water Pump Horsepower: Two (2) 7.5 HP.

Electrical Utility: Full Load Amps (FLA) 80/40 (208-230/460V).

Make-up Water Requirement: 15 gpm.

Ion Exchange Details:

Resin Volume per Vessel: 22 ft³.

Total Cation Grains Capacity: 440,000 grains.

Total Anion Grains Capacity: 396,000 grains.

Regeneration Consumption/Waste:

32% HCl per Cycle: 29 gallons.

50% NaOH per Cycle: 16 gallons.

Cation Waste per Cycle: 825 gallons.

Anion Waste per Cycle: 1,000 gallons.

-

System Flow Rate: 75 gpm

Approximate Footprint: 10’ x 16’ x 10’ H (Duplex Series).

Tank Volumes:

Minimum Feed Rinsewater Tank Volume: 3,000 gallons.

Minimum DI Water Holding Tank Volume: 4,000 gallons.

Pumps & Utilities:

Feed Pump Horsepower: Two (2) 10 HP.

DI Water Pump Horsepower: Two (2) 10 HP.

Electrical Utility: FLA 110/55 (208-230/460V).

Make-up Water Requirement: 20 gpm.

Ion Exchange Details:

Resin Volume per Vessel: 30 ft³.

Total Cation Grains Capacity: 600,000 grains.

Total Anion Grains Capacity: 540,000 grains.

Regeneration Consumption/Waste:

32% HCl per Cycle: 45 gallons.

50% NaOH per Cycle: 22 gallons.

Cation Waste per Cycle: 1,200 gallons.

Anion Waste per Cycle: 1,400 gallons.

-

System Flow Rate: 115 gpm

Approximate Footprint: 13’ x 19’ x 10’ H (Duplex Series).

Tank Volumes:

Minimum Feed Rinsewater Tank Volume: 4,500 gallons.

Minimum DI Water Holding Tank Volume: 6,000 gallons.

Pumps & Utilities:

Feed Pump Horsepower: Two (2) 15 HP.

DI Water Pump Horsepower: Two (2) 15 HP.

Electrical Utility: FLA 160/80 (208-230/460V).

Make-up Water Requirement: 25 gpm.

Ion Exchange Details:

Resin Volume per Vessel: 40 ft³.

Total Cation Grains Capacity: 800,000 grains.

Total Anion Grains Capacity: 720,000 grains.

Regeneration Consumption/Waste:

32% HCl per Cycle: 56 gallons.

50% NaOH per Cycle: 30 gallons.

Cation Waste per Cycle: 1,600 gallons.

Anion Waste per Cycle: 1,800 gallons.

-

System Flow Rate: 135 gpm

Approximate Footprint: 14’ x 23’ x 10’ H (Duplex Series).

Tank Volumes:

Minimum Feed Rinsewater Tank Volume: 6,500 gallons.

Minimum DI Water Holding Tank Volume: 8,000 gallons.

Pumps & Utilities:

Feed Pump Horsepower: Two (2) 20 HP.

DI Water Pump Horsepower: Two (2) 20 HP.

Electrical Utility: FLA 210/105 (208-230/460V).

Make-up Water Requirement: 35 gpm.

Ion Exchange Details:

Resin Volume per Vessel: 55 ft³.

Total Cation Grains Capacity: 1,100,000 grains.

Total Anion Grains Capacity: 990,000 grains.

Regeneration Consumption/Waste:

32% HCl per Cycle: 77 gallons.

50% NaOH per Cycle: 41 gallons.

Cation Waste per Cycle: 2,200 gallons.

Anion Waste per Cycle: 2,400 gallons.

HFX DOWNLOADS

System Adders and Enhancements

Optimized Regeneration Control (ORC): An optional add-on that provides advanced oversight and precision control of the ion exchange resin regeneration utilizing dedicated instrumentation for measuring and controlling the quality of the regenerant solution and regeneration waste stream in millisiemens (mS). This feature automatically controls the chemical dosage of drawn acid and caustic solutions and reduces chemical consumption and wastewater production. Available on all WI-RIX and HFX models.

HFX High Purity (HP) Option: Addition of a duplex polishing cation exchanger skid. It is necessary if the required water quality is better than 3 uS/cm and produces DI water in the range of 3–5 MegOhm.

HFX Enhanced Pre-treatment (EP) Option: Includes the addition of Macrolite® multi-media backwashable filters. This option is designed to handle the removal of up to 50 mg/L suspended solids larger than 5-microns.

Other Optional Equipment:

Submicron Filtration for low particle count water.

Neutralizer for automatic neutralization of regenerants.

Chemical Reuse Option (saves up to 30% of chemical costs).

Monitoring and Data Logging for SPC and ISO records.