Manufacturing best-in-class

regenerable ion exchange systems

For Industrial Water Recycling, Deionization & Metal Scavenging with cutting-edge engineering to ensure consistent product water quality with reduced chemical usage and wastewater for the lowest operating cost.

Starting in 2005 with counter-current regeneration of packed-resin beds that reduced chemical usage & wastewater by 50-60% and “feed-forward” grain counting to trigger regenerations before DI water quality diminishes, we added in 2012 product water pH-monitoring to independently trigger cation or anion regeneration, that we further enhanced in 2022 with Optimized Regeneration Control (ORC) which adjusts chemical feed by measuring regenerant uS to proportionally control an electrically-actuated valve instead of the operator checking SpG and recovers 20% of wastewater based on its uS to maximize water recovery.

In partnership with Georg Fischer (GF) whose process automation including +GF+ Signet measurement and control and +GF+ Piping Systems have been the cornerstone of our ion exchange and wastewater treatment systems since Day 1 and recently began final assembly of our WI-RIX systems.

See how we utilize GF process automation & piping systems while “Building our best system ever - Every time.”

What We Do

We deliver turnkey water treatment systems that are engineered to your specific process and rinse water needs. Our core technologies include…

Regenerable Ion Exchange Systems – Recycle rinse water with high recovery rates (>95%) for reuse as deionized-quality water starting from 12 GPM.

High-Flow Ion Exchange Systems – Ideal for large-scale applications needing consistent, high-purity water ranging from 55-135 GPM.

Selective Metal Recovery Systems – Remove and reclaim dissolved metals to meet discharge limits or enable resource recovery.

Advanced Pretreatment Solutions – Mechanical filtration utilizing specialty medias based on application.

Custom Wastewater Treatment – From chemical precipitation to pH adjustment and heavy metals removal.

All systems are fully integrated, modular, and built in-house

WhO WE SERVE

We proudly serve industries where rinse and process water quality are critical — especially…

Metal finishing & plating

Aerospace & defense manufacturing

Printed circuit board (PCB) production

Anodizing operations

General industrial manufacturing

Our clients rely on us to improve water efficiency, lower operating costs, and stay ahead of environmental regulations.

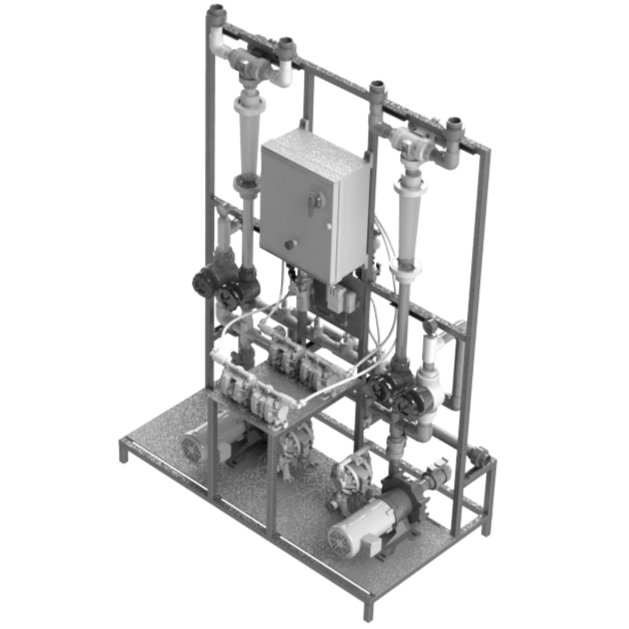

Standardized Skid-mounted Systems

WI-RIX SERIES

REGENERABLE ION EXCHANGE

Our newest standardized system, the single skid WI-RIX is customized for water recycling (WR), deionization (DI) or metal scavenging (MS), for 12- or 25-gpm continuous service with alternating duplex multi-media, cation & anion resin vessels

12 GPM

25 GPM

HFX SERIES

HIGH FLOW ION EXCHANGE

Inherited from Kinetico Engineered Systems and incorporating all of the features of the WI-RIX, the multi-skid HFX is available from 35 to 135-gpm of continuous service, based on columns size and tanks volumes, with redundant alternating duplex feed & DI water pumps providing 24/7 operation

55-135 GPM

Batch & CONTINUOUS

WASTEWATER TREATMENT

Generally combined and integrated with WI-RIX and HFX systems, Water Innovations Batch Treatment (WI-BT) and Continuous Treatment (WI-CT) are built upon our 20 years of experience with wastewater treatment and knowledge of proprietary metal precipitants & coagulants

BATCH

CONTINUOUS

Ready to Rethink Water in Your Process?

Contact Water Innovations today to discuss a tailored solution for you.

Beyond Equipment

We don’t just deliver systems; we build long-term partnerships. Our comprehensive services include:

Engineering & Process Analysis

On-Site Installation & Startup

Operator Training & Documentation

Remote Monitoring & Technical Support

Maintenance & System Upgrades

With our in-house fabrication, testing, and service team, we ensure every solution performs to spec — on day one and for years to come.